Water Treatment in the Food & Beverage Industry | RO Systems

There are few industries which require as much need for purified water than the food & beverage industry. Our history working within this industry shows us that most beverage companies have their own standards in regards to the level of water purity required for the production of their soft drinks. Our extensive background with providing water treatment in the Food and Beverage industry allows us to understand the specific needs of our clients. We use this knowledge to conjure original water treatment solutions with first-rate standards:

- Ensuring compliance with the stringent decontamination and refinement specifications for the production of safe water.

- Preventative solutions which will prevent the spread and health risk of Legionella.

Pure Aqua is motivated with our continuous success in improving the water quality of our clients within the food and beverage industry. We have done this through cost reductions from production and standardized equipment enhancements, reusing treated wastewater, and delivering water well oil-field based solutions which provides a substitute source of water supply.

Our water treatment technologies employed for the food & beverage markets include:

Water Treatment in Food Industry

The importance of water treatment in the food industry comes from the need to remove any presence of microorganisms. To avoid any sort of degradation, water in use for cooking or specifically applied to the food must be potable and of good quality. This involves the absence of dissolved minerals that make water too hard or alter its taste.

Product water makes up the majority of the fluid in the food industry, so it's necessary to treat it to meet taste goals. For high purity, water treatment further than that needed to meet potable water requirements is frequently required.

BOTTLING PURIFICATION PROCESS

Beverage bottling usually starts with municipal tap water, coming right out of the water sources from the cities where the plant resides. Tap water like this is certainly drinkable, but usually has an element of hardness, or deposits of heavy metals (usually from the pipes that transport the water) that detract from the taste. Water softeners and reverse osmosis are perfect for creating pure, potable water.

Once a beverage company has a large sample of purified water, a "blank slate", if you will, to work with, they typically begin adding their own unique mixtures of minerals, metals, carbon dioxide (the "fizz" in soda), sugars, syrups, and food coloring to create the soft drinks that we know and love. Once this solution is thoroughly mixed, it is packed into sealed bottles or cans and transported to its destination. Alcoholic beverages go through a similar process, but typically baked with yeast and some form of grain or fruit added to them to produce alcohol. Because of the simplicity of the premise of beverage bottling, a majority of companies that make beverages do it in small businesses.

Bottled Water Vs. Tap Water:

Contrary to popular belief, "mountain fresh" or "spring" water also come from the same sources as the tap water in your sink. Why does it taste so much better than tap water, you may ask? Bottled water, believe it or not, goes through the same process as any soft drink. The municipal tap water is purified (ideally with a reverse osmosis system, softener, or sterilizer), making a "blank slate" for the company to work with, and then rather than adding syrups and sugars, bottled water goes through a bit of a different process.

Reverse Osmosis

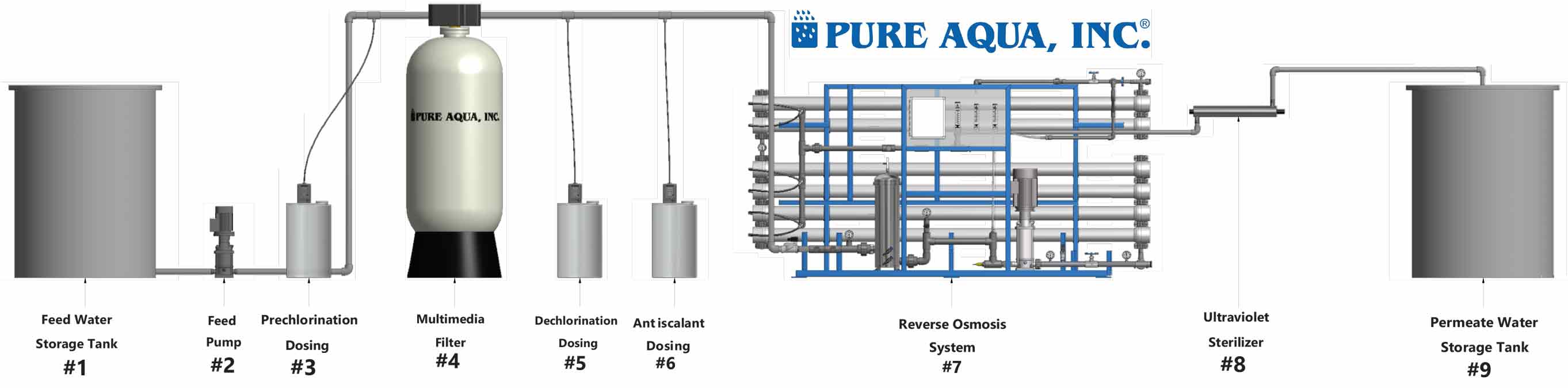

Reverse osmosis is the foundation of Pure Aqua's water treatment process that is used in the beverage industry .

Reverse osmosis systems work by applying immense pressure to drive water across a membrane while siphoning out impurities. Due to this immense pressure, impurities will arise and cause one side of the membrane to become more concentrated than the other. Only the ultra pure water is capable of passing through the membrane, while the dissolved impurities, which are unable to be eliminated by conventional filtration are trapped and removed by Pure Aqua’s reverse osmosis water treatment system.

Our reverse osmosis systems are designed with leading technology to maximize water quality and purification. The water will become purified once it passes through different layers within the RO membranes, which filters out all of the total dissolved solids (TDS).

Regardless of whether or not a minimal variation in quality remains, an alarm is set off which shuts the entire system down. The end result is a quality of fresh water that is unmatched. If you don't believe us then check out our client testimonials who have went in detail, comparing the quality our RO membranes have on their water systems next to our competitors.

The Best Tasting Water:

Companies that make bottled waters send experts in the environmental industry out to regions where the water tastes fresher than our tap water, such as clear rivers, freshwater lakes, and mountain waterfalls as examples. The experts take small samples of the water in these areas and meticulously test and calculate the mineral and metal contents of this water, creating a recipe of sorts to replicate the taste. Then, once they have instructions on how much of what minerals and metals to add, the process becomes just like any other soft drink, dissolving these substances in the water and then bottling them for shipping.

For more information please view/download the industry brochure

Completed Water Treatment Projects:

ENGLISH arrow_drop_down

ENGLISH arrow_drop_down

ESPAÑOL

ESPAÑOL ???????

??????? PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS