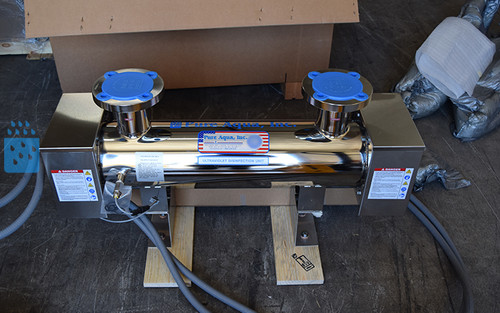

Pure Aqua’s UVC systems virtually eliminate microbiological contaminants without using potentially hazardous chemicals. Water enters through the bottom port of the ultraviolet generator cell and swirls around a low pressure mercury vapor lamp, which emits powerful ultraviolet light energy at 235.7nm wave length. Bacteria, viruses and other micro-organisms absorb the light energy which disrupts their DNA, and are destroyed safely inside a factory tested stainless steel cell. The treated water then exits through the top port of the cell and is ready for consumption.

| Benefits and Advantages of Commercial UV Sterilizers UVC: | ||

|---|---|---|

|

|

|

How Effective are UV Sterilizers for Water Treatment?

UV water sterilizers are highly effective against all microbiological concerns, such as viruses and bacteria. Despite this, many microorganisms have greater resistance to UV light systems, which renders low-power UV sterilizers ineffective in eliminating these infectants. For this reason, we make sure to specifically design practicable UV water treatment systems to remove all unwanted microorganisms.

Pure Aqua actively engineers and manufactures thousands of commercial UV purification systems. Our engineering process is straightforward and designed to provide safe, and effective UV water sterilizers in quick fashion. This procedure allows for products that maintain regular, or irregular disinfection in the absence of significant attention or assessment. While our commercial UV systems require minimal maintenance, some types of upkeep are still necessary, such as:

Lamp Substitution

- Unlike normal fluorescent lamps, Ultra Violet lamps do not sizzle out, and are instead solarized, which reduces heat energy by about 60% of a new lamp after one year of daily usage. For instance, new lamps can generate dosage levels over 55,000 µW-s/cm2. However, this level declines to about 30,000 µW-s/cm2, which is the minimum dosage required to adequately eliminate contaminants. When it falls below this level then it is time to replace the UV lamp. Side note, if you have a habit of regularly switching the lamp on and off then the life of the lamp will be shortened dramatically.

No Overheating

- As with the case with other lamp types, the ultraviolet lamp units our engineers utilize have no chance of overheating. Therefore, the need for acquiring supplementary equipment to address issues of overheating is erased.

Cleaning the quartz sleeve

- Cleaning your UV system becomes a necessity to prevent the accumulation of dirt around the quartz sleeve. Unclean ultraviolet sterilizers will inevitably lead to impassable quartz sleeves, and effectively hinder the UV rays from passing through the sleeve and into the water. To preserve sufficient purity, glass throughout the lamp must be cleaned on a regular basis. The frequency of cleaning is based on the quality of the water and will be advised to install a pretreatment such as media or cartridge filters.

Tracking Ultra Violet Dosage

- Meters are used to ascertain the intensity of the UV light, and the degree of which the radiation is passing through the quartz sleeve. If the UV dosage is found to be too low then the disinfection process will be ineffective. It is also useful in specifying when the time for cleaning the quartz sleeve and replacing the UV lamp.

Questions & Answers

Should I filter my water before UV light disinfection?

- Filtering water before entering it into a UV purification system is crucial since the clearer water increases the UV transmittance ratio. This means that the UV system will be able to transmit light waves with higher energy, which will penetrate the water more effectively and sterilize it. Consequently, it’s of utmost importance to monitor your UVT and observe its levels to keep it over the manufacturer’s minimum requirement for effective disinfection.

How to select the right UV system?

- Every UV light system has pretreatment requirements, such as a certain level of turbidity, iron, hardness, and ultraviolet transmittance (UVT). Unclear water will result in a low ultraviolet transmittance, which reduces the effectiveness of disinfection, since the water will be less able to transmit ultraviolet light. To compensate for this issue, you will need a larger UV system with a higher flow rate. However, if your water is perfectly clear then the UVT percentage should be just fine.

| Minimum Water Quality Requirements: | Operation Specifications: |

|

|

|

Model |

Flow Rate (GPM) (95% UVT ) |

Power Consumption |

In/Out Port Size |

Chamber Material |

Chamber Dimensions (in.) |

Installation Orientation |

Shipping Weight (lbs) |

||

|

North America |

EU CEE |

30 mJ/ cm² |

40 mJ/ cm² |

(Watts) |

|||||

|

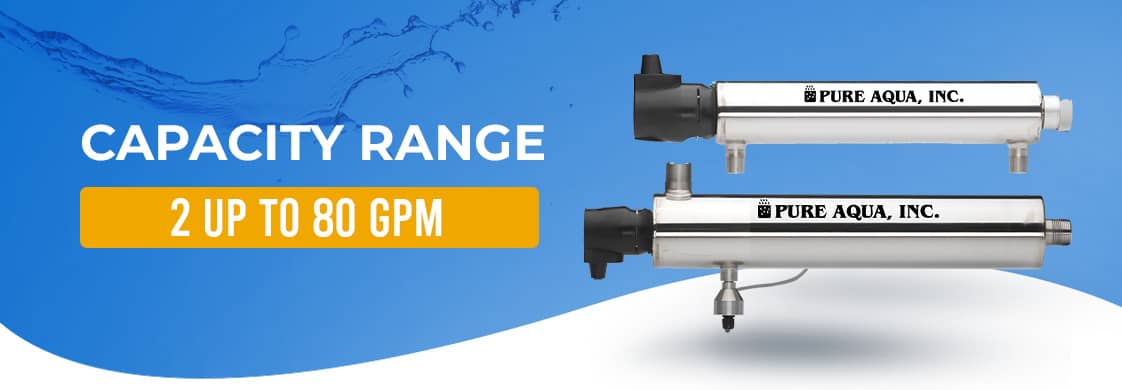

S2Q-PA |

S2Q-PA/2 |

3 |

2 |

22 |

1/2" MNPT |

SS304 |

17x2.5 |

Vertical or Horizontal |

7 |

|

S3 |

S3/2 |

5 |

3.5 |

32 |

Combo 3/4" FNPT /1" MNPT |

13x3.5 |

8 |

||

|

S7 |

S7/2 |

9 |

7 |

35 |

3/4"-1" MNPT Combo |

17.75x3.5 |

12 |

||

|

S14 |

S14/2 |

18 |

14 |

60 |

3/4"-1" MNPT Combo |

23.5x3.5 |

17 |

||

|

S18 |

S18/2 |

24 |

18 |

70 |

1" MNPT |

30.3x3.5 |

19 |

||

|

S26 |

S26/2 |

34 |

26 |

95 |

1.5" MNPT |

45x3.5 |

29 |

||

|

S37 |

S37/2 |

45 |

37 |

160 |

1.25" MNPT x 1" FNPT Combo |

SS316 |

31x4 |

Vertical |

28 |

|

S60 |

S60/2 |

80 |

60 |

230 |

2" MNPT |

41x4 |

31 |

||

|

For more information, please view/download our "Data Sheet" |

|||||||||

[/custom-specifications]

|

Standard Features: |

Available Options: |

|

|

[/custom-features]

|

The ideal applications for a UV Sterilizer include: |

||

|

|

|

[/custom-usage]

Here at Pure Aqua, Inc., we engineer and build all of our water treatment systems in-house.

Our turn-key water treatment systems are all pre-engineered using the latest CAD technology available.

This enables our teams to build and deliver treatment systems to our customers with quick turnaround times.

Many of our customers require custom engineered systems. These are typically built around similar core systems and thus allowing for improved turnaround times, even for one-off designs.

-

Ultraviolet Sterilizer

Gets the job done in removing biological organisms from feed water. It produces highly purified water.

-

UV Sterilizer

Produces extremely pure water. Saves business costs due to not requiring chemicals. Excellent product!

- 360view:

- https://cdn11.bigcommerce.com/s-1x0ys7yqwf/content/360Views/Coming%20Soon.0.html

- 360image:

- https://cdn11.bigcommerce.com/s-1x0ys7yqwf/product_images/uploaded_images/360view-wireframe-small.jpg

ENGLISH

ENGLISH

ESPAÑOL

ESPAÑOL العربية

العربية PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS