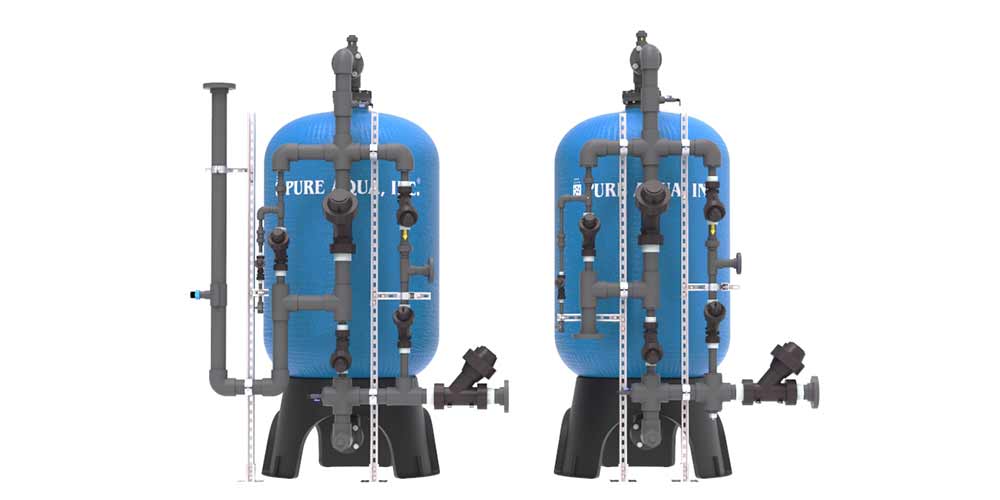

Engineered for medium-sized deionization (DI) applications, these dependable units feature the same precision electronics and performance characteristics as their large-scale counterparts, all in a smaller, using diaphragm valves package. Applications cover the full spectrum of industrial, commercial, medical, boiler feed water uses. Pure Aqua offers a wide range of IX systems and resin types for general manufacturing and industrial applications, as well as special grades of resin for critical applications such as food & beverage, nitrate removal, arsenic removal, healthcare, biopharmaceutical and microelectronics.

Advantages of choosing a Pure Aqua Dual-Bed Deionizer include:

- Two-Bed Automatic “Package” Deionizers are available in sizes from 2-8 GPM, and at rated exchange capacities:of 40,000 to 100,000 grains. These systems are fully-assembled, with all wiring and tubing completed requiring minimum installation and start-up effort. Skid mounting is an option.

- Exchanger vessels are all non metallic construction, rated at 150 psi.

- Piping is Schedule 80 PVC, with solvent-welded joints, rigidly supported on unit strut channels.

- Valves-Noryl diaphragm type, pneumatically operated, with integral travel stops for flow regulation.

- Internal distributions are PP / schedule 80 PVC and radial lateral design.

- The provided cation resin is a high capacity strong acid, bead-form, conventional gel polystyrene sulfonated exchange resin which is shipped in the hydrogen form ready for immediate use. Resin capacity information is based on 6 lbs. of HCL per cu. ft. of exchange resin. The provided anion is a high capacity strong base, type 2, bead form, conventional gel exchange resin which is shipped in the chloride form for maximum storage life. Resin capacity information is based on 6 lbs. of NaOH per cu. ft. of exchange resin.

- Optional stainless steel liquid filled pressure gauges, sample valves, flow indicator on water inlet, and inlet pressure reducing valve.

|

Pre-Treatment Systems |

Post-Treatment Systems |

Other Systems |

|

|

|

[custom-specifications]

|

Model No. |

Nominal |

Service Flow Rate GPM |

Pipe |

Mineral |

Resin Quantity (ft)3 |

Shipping Weight (lbs) |

|||

|

Cont. |

Peak |

BW |

Cation |

Anion |

|||||

|

DM14-Q-FRP |

65,000 |

4 |

10 |

7.8 |

1" |

14" * 65" |

3 |

3 |

800 |

|

DM16-Q-FRP |

80,000 |

6 |

12 |

9 |

1" |

16" * 65" |

4 |

4 |

1,200 |

|

DM18-Q-FRP |

100,000 |

8 |

14 |

10 |

1" |

18" * 65" |

5 |

5 |

1,400 |

|

DM21-Q-FRP |

140,000 |

12 |

18 |

15 |

1.5" |

21" * 65" |

7 |

7 |

1,650 |

|

For more information, please view/download our "Data Sheet" |

|||||||||

[/custom-specifications]

|

Standard Features: |

Available Options: |

|

|---|---|---|

|

|

|

[/custom-features]

|

The Industries and applications in which a dual-bed deionizer find use include: |

|

|

|

Here at Pure Aqua, Inc., we engineer and build all of our water treatment systems in-house.

Our turn-key water treatment systems are all pre-engineered using the latest CAD technology available.

This enables our teams to build and deliver treatment systems to our customers with quick turnaround times.

Many of our customers require custom engineered systems. These are typically built around similar core systems and thus allowing for improved turnaround times, even for one-off designs.

-

great quality of systems

We ordered one last month and it was able to satisfy our need on time. Thanks!

-

Fast delivery

shipped same day...fast delivery, thanks

-

fast shipping

Better prices here!

- 360view:

- https://cdn11.bigcommerce.com/s-1x0ys7yqwf/content/360Views/DM18.10.html

- 360image:

- https://cdn11.bigcommerce.com/s-1x0ys7yqwf/product_images/uploaded_images/360view-wireframe-small.jpg

ENGLISH

ENGLISH

ESPAÑOL

ESPAÑOL العربية

العربية PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS