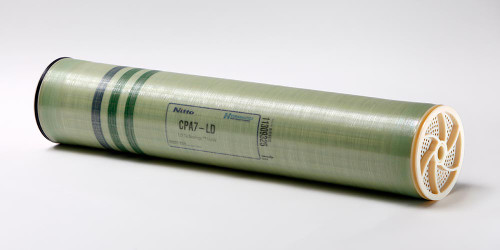

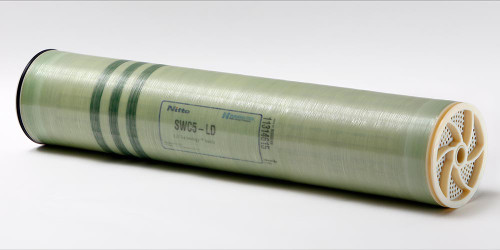

CPA6-LD is the fifth generation CPA brackish water RO membrane and has the best rejection of all of its predecessors at 99.8%. This 400 sq. ft. membrane operates at a higher feed pressure than CPA5-LD but it has the highest rejection in the CPA family.

CPA6-LD membranes are designed with Low Differential Pressure LD TM Technology designed to minimize colloidal fouling. They have 37.0 m² (400 ft²) membrane area. Using CPA6-LD results in cost saving while still getting a high rejection from membranes.

CPA6-MAX has the same high rejection membrane of CPA6-LD, but features a 10% increase in membrane area at 440 sq.ft. CPA6 MAX is a preferred choice for feed waters of low turbidity and silt density index such as brackish well waters.

CPA6-LD and CPA6-MAX membranes are available in diameters of 8.0 inches only.

[custom-specifications]

CPA6-LD Specifications:

- Permeate Flow: 8,000 gpd (30.3m3/d)

- Salt Rejection: 99.75 % (99.6 % minimum)

- Type Configuration: Low Fouling Spiral Wound

- Membrane Polymer: Composite Polyamide

- Membrane Active Area: 400 ft2 (37.1m2)

- Feed Spacer: 34 mil (0.864 mm)

The stated performance is initial (data taken after 30 minutes of operation), based on the following conditions:

- 1500 PPM NaCl solution

- 225 psi (1.55 MPa) Applied Pressure

- 77 °F (25 °C) Operating Temperature

- 15% Permeate Recovery

- 6.5 - 7.0 pH Range

[/custom-specifications]

[custom-features]

Standard Operating Limits:

- Maximum Applied Pressure: 600 psig (4.14 MPa)

- Maximum Chlorine Concentration: < 0.1 PPM

- Maximum Operating Temperature: 113 °F (45 °C)

- pH Range, Continuous (Cleaning): 2-11 (1-13)

- Maximum Feedwater Turbidity: 1.0 NTU

- Maximum Feedwater SDI (15 mins): 5.0

- Maximum Feed Flow: 75 GPM (17.0 m3/h)

- Minimum Ratio of Concentrate to Permeate Flow for any Element: 5:1

- Maximum Pressure Drop for Each Element: 15 psi

[/custom-features]

[custom-usage]

- Desalting of Well Waters – Municipal Drinking Water

- Reducing TDS Prior to Ion Exchange

- Boiler Make-Up Water

- Ultrapure Water for Semi-Conductor Manufacture

[/custom-usage]

-

Excellent customer service

You guys are very professional

ENGLISH

ENGLISH

ESPAÑOL

ESPAÑOL العربية

العربية PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS