Designed as a cost-effective, high performance system for maximum water confidence

The Swift Beverage Series offers validated UV for beverage disinfection that exceeds FDA and USEPA compliance requirements. This proven protection safeguards against virtually all microorganisms, including Cryptosporidium, Giardia and Adenovirus, proving greater safety and peace of mind.

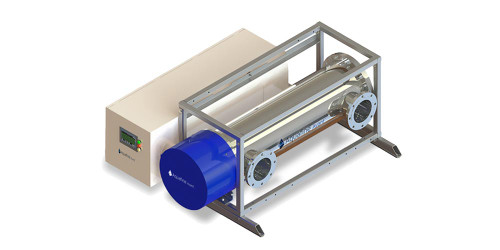

Featuring the industry’s most advanced low-pressure, high-output (LPHO) amalgam lamp technology, the Swift Beverage series consists of a 316L stainless steel treatment chamber and a NEMA-3R stainless steel control cabinet featuring a microprocessor-based controller.

The compact size maximizes installation flexibility and preserves floor space with the ability to mount in line, horizontally or vertically and complies with stringent NSF 61 standard.

Proven performance – full bioassay validation (USEPA)

186 mJ/cm2 UV doses meets the stringent, internationally recognized USEPA standard – having undergone comprehensive validation at a wide range of flow rates and UV transmittance levels.

Assurance of NSF 61 compliance

NSF/ANSI 61: Drinking Water System Components – Health Effects ensure the raw materials are safe and have been properly tested against radionuclides and other naturally occurring volatile organic compounds.

Low operation and maintenance cost

Low pressure high output Amalgam lamps save up to 62% power cost and request much lower maintenance.

Compact footprint for installation flexibility

Can handle maximum flow capacity in minimal space. Its compact design allows it to be installed vertically or horizontally in restrictive spaces, thereby lowering installation costs.

[custom-specifications]

| Model: Swift Beverage | SBV300 | SBV600 | SBV1200 | SBV1800 |

|---|---|---|---|---|

| Maximun Flow Rate-Validated | ||||

| DISINFECTION @ 97% UVT (M³/HR) | 106-832 (24 - 189) GMP (M³/HR) | |||

| Numbers of Lamps (LPHO) | 3 | 6 | 12 | 18 |

- MODEL SHOWN: SwiftBeverage Series // INDUSTRIES: Food & Beverage //

- FLOW RATES: 25-850 GPM // APPLICATIONS: Bioassay Validated Disinfection //

- DESIGN CAPABILITIES: Custom Configurations or Skid Capabilities

[/custom-specifications]

[custom-features]

- Proven performance – full bioassay validation (USEPA)

- Assurance of NSF 61 compliance.

- Low operation and maintenance cost

- Compact footprint for installation flexibility

- Guaranteed performance and comprehensive warranty

[/custom-features]

[custom-usage]

- Food & Beverage

- Pharmaceutical

- Bioassay Validated Disinfection

[/custom-usage]

[custom-documents]

[/custom-documents]

-

ISO 9001

Thank you for terrific customer support!

ENGLISH

ENGLISH

ESPAÑOL

ESPAÑOL العربية

العربية PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS