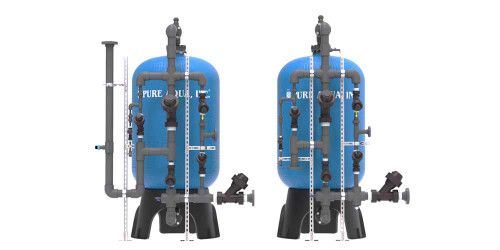

This is a Commercial Dual Bed Deionizer designed for industrial water treatment. The capacity of the system is 14 GPM, and includes reinforced fiberglass tanks, and many other high quality parts that can be seen in our video.

- Reinforced Fiberglass Tanks

- Polyethylene Inner Shell

- Air operated diaphragm valves

- PP/PVC sch 80 internal piping and distributor

- Schedule 80 PVC face piping

- Flowmeter

- Digital Stager

[custom-specifications]

Water Challenges: This project consisted of problems related to scaling issues, which includes silica being observed regularly in water sources. Scaling problems are correlated to the productivity of industrial facility functioning, including the consistency and quantity of water throughput, and the cost of operating/replacing the equipment used.

[/custom-specifications]

[custom-features]

[/custom-features]

[custom-usage]

Our reverse osmosis systems provide manufacturers with several other advantages such as:

- Scaling and silica reduction

- Improved efficiency of boiler feeds via decreased boiler deposits

- Less need of water used in the course of operations

- Eradication of greater than 99% of suspended solids in the feed water, such as the formation of scale which reduces heat transfer

- Lower alkalinity amongst the boiler feedwater that effects in lower use of amine

- Decreases in the want of make-up water to heat and smooth heat transfer areas and savings in fuel cost

-

Deionizer

Thank you for this wonderful deionizing system

ENGLISH

ENGLISH

ESPAÑOL

ESPAÑOL العربية

العربية PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS