Overview

- Location: California, USA

- Application: Water purification for a sports arena (drinking, cleaning, and equipment use)

- System Capacity: 200 GPM

- Water Source: Municipal feed water (up to 1,000 ppm TDS)

- System Type: Brackish Water Reverse Osmosis System with full pretreatment and post-treatment

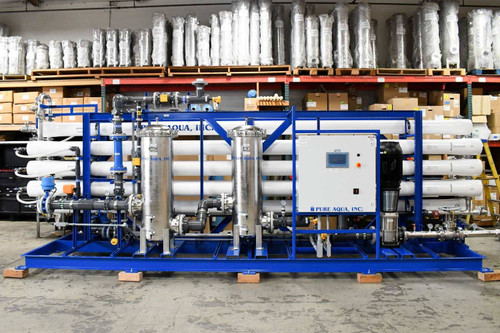

- Model: TW-360K-8680

Key Components:

- Pretreatment:

• Pre-chlorination chemical dosing system – oxidation of organics and microbial control

• (2) 72" Multimedia Filters (SSH epoxy-coated carbon steel tanks) – turbidity & suspended solids removal

• (3) 72" Activated Carbon Filters (SSH epoxy-coated carbon steel tanks) – chlorine, taste & odor removal

• Dechlorination chemical dosing system – protects RO membranes

• Antiscalant chemical dosing system – prevents membrane scaling - Reverse Osmosis System:

• Model TW-360K-8680, production rate 200 GPM, feed TDS up to 1,000 ppm

• Powder-coated carbon steel frame

• (8) 8" FRP pressure vessels (300 PSI)

• (48) 8" TFC spiral wound membranes

• High-pressure pump

• 5-micron stainless steel cartridge filter housing

• Pressure gauges, flow meters (feed, reject, product)

• Low & high pressure switches

• Siemens S7-1200 PLC control panel with automation & alarms

• High pressure piping: 316 stainless steel

• Low pressure piping: Schedule 80 PVC - Post-Treatment:

• Post-chlorination chemical dosing system – final disinfection before distribution

• Post pH adjustment chemical dosing system – stabilizes pH for safe distribution

[custom-specifications]

The sports arena required a system that could:

- Treat large volumes of municipal water daily for thousands of users.

- Remove suspended solids, chlorine, and dissolved salts for taste, safety, and equipment protection.

- Operate continuously in a high-demand environment with minimal downtime.

- Deliver consistent water quality to meet health and safety regulations.

- Provide a compact yet scalable solution for a large public venue.

[/custom-specifications]

[custom-features]

Pure Aqua delivered a 200 GPM Brackish Water RO System (Model TW-360K-8680), fully integrated with pretreatment and post-treatment for maximum reliability:

- Multi-Stage Treatment: Chemical dosing, multimedia, and carbon filters protect membranes and optimize performance.

- Advanced RO Design: (48) TFC membranes in (8) FRP pressure vessels produce consistent, high-quality water.

- Automated Controls: Siemens PLC ensures efficient operation with alarms and monitoring.

- Robust Construction: Stainless steel and epoxy-coated tanks provide long-term durability.

- Complete Water Solution: From pretreatment to post-treatment, the system meets all water quality and operational demands of a large-scale sports arena.

[/custom-features]

[custom-usage]

- High-Quality Water: Meets drinking and facility utility standards.

- Automated Operation: Siemens PLC and advanced sensors reduce manual intervention.

- Durable Design: 316 SS and epoxy-coated tanks withstand heavy-duty continuous operation.

- Comprehensive Pretreatment: Protects membranes, extending lifespan and improving efficiency.

- Low Maintenance: Streamlined operation ensures minimal downtime and reliable performance.

Join our subscribers for more videos

ENGLISH

ENGLISH

ESPAÑOL

ESPAÑOL العربية

العربية PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS