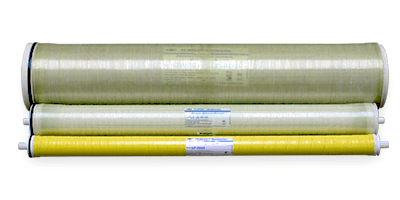

DUPONT FILMTEC HSRO-4040-FF is a heat sanitizable reverse osmosis element that delivers exceptional quality water with the added capability to withstand sanitization with hot water. HSRO elements, manufactured on advanced automated equipment, have the highest active membrane area allowing system designs with either lower operating flux or cost savings from fewer membrane elements. The full-fit configuration minimizes stagnant areas and is an ideal choice for applications requiring a sanitary design. All components comply with U.S. Food & Drug Administration standards

Advantages

- Heat Sanitizable

- High flux rates

- Full-fit design

- consistent quality from automated rolling;

- Filmtec performance and quality

Important Information

New HSRO heat sanitizable spiral elements must be pre-conditioned prior to initial use by exposure to hot water. An appropriate conditioning procedure consists of the following:

- Flush to drain with suitable quality water at low pressure and low permeate flow rate.

- Recycle warm water (45°C or less) at very low pressure (< 25 psig trans-membranepressure with a maximum feed pressure of 45 psig (3 bar)).

- Introduce hot water to the system to increase temperature to 80°C (176°F).

- Keep trans-membrane pressure below 25 psig (1.7 bar) when warm or hot water (45°Cor higher) is being fed to the membranes.

- Maintain temperature for 60-90 minutes.

- Allow system to cool to 45°C or below.

Operation Guidelines

Avoid any abrupt pressure or cross-flow variations on the spiral elements during start-up, shutdown, cleaning or other sequences to prevent possible membrane damage. During start-up, a gradual change from a standstill to operating state is recommended as follows:

- Feed pressure should be increased gradually over a 30-60 second time frame.

- Cross-flow velocity at set operating points should be achieved gradually over 15-20seconds.

- Permeate obtained from first hour of operation should be discarded.

General Information

- Keep elements moist at all times after initial wetting.

- If operating limits and guidelines given in this bulletin are not strictly followed, the limitedwarranty will be null and void.

- To prevent biological growth during prolonged system shutdowns, it is recommendedthat membrane elements be immersed in a preservative solution.

- The customer is fully responsible for the effects of incompatible chemicals and lubricantson elements.

- Maximum pressure drop across an entire pressure vessel (housing) is 60 psi (4.1 bar).

- Avoid static permeate-backpressure at all times.

Specifications

| Product | Part Number | Active Area | Applied Pressure | Permeate Flow Rate | Stabilized Salt Rejection (%) | |||

|---|---|---|---|---|---|---|---|---|

| ft2 | (m2) | psig | (bar) | gpd | (m3/d) | |||

| HSRO-4040-FF | 98592 | 90 | (8.4) | 150 | (10.3) | 1,900 | (7.2) | 99.5 |

DUPONT FILMTEC™ HSRO heat sanitizable reverse osmosis membrane elements deliver outstanding quality water with the added capability to withstand sanitization with hot water. Hot Water sanitization eliminates the need for chemical sanitizers. The full-fit configuration minimizes stagnant areas and is optimal for applications requiring a sanitary design. All components comply with FDA standards.

Operating Limits

- Membrane Type Polyamide Thin-Film Composite

- Maximum Operating Temperature 113°F (45°C)

- Maximum Sanitization Temperature (@ 25 psig) 185°F (85°C)

- Maximum Operating Pressure 600 psig (41 bar)

- Maximum Pressure Drop 15 psig (1.0 bar)

- pH Range, Continuous Operation 2 - 11

- pH Range, Short-Term Cleaning 1 - 12

- Maximum Feed Silt Density Index SDI 5

- Free Chlorine Tolerance < 0.1 ppm

- Medical applications

- Sanitary uses

-

always in stock

Service was exceptional. Great company!

ENGLISH

ENGLISH

ESPAÑOL

ESPAÑOL العربية

العربية PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS