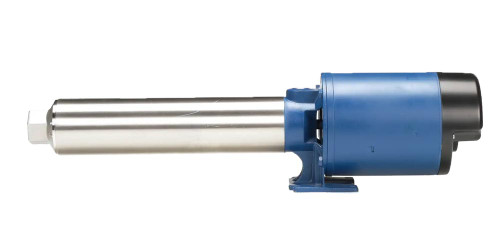

Cast Iron, Powder Coated and Stainless Steel Booster Pumps PB05, PB07, PB10, PB19, PB27, PB35

Pure Aqua also distributes Cast Iron Model water pump components (cast iron inlet and discharge castings, 304 stainless steel pump shell, 416 stainless steel hex pump shaft and carbon/ceramic seal with Buna N rubber parts), Powder Coated Model pump components (powder coated cast iron inlet and discharge castings, 304 stainless steel pump shell, 416 stainless steel hex pump shaft and carbon/ceramic seal with Buna N rubber parts), and Stainless Steel Model pump components (stainless inlet and discharge castings, 304 stainless steel pump shell, 316 stainless steel hex pump shaft and carbon/ceramic seal with Viton rubber parts).

Flint & Walling Commercial Water Pumps:

MATERIAL CONSTRUCTION

| Component Description | Stainless Steel Models 5, 7, 10, 19, 27 & 35 GPM 1/3 thru 3 HP | Powder-coated Models 5, 7, 10, 19, 27 & 35 GPM 1/3 thru 3 HP | Cast Iron Models 5, 7, 10, 19, 27 & 35 GPM 1/3 thru 3 HP |

| Suction and Discharge Casting | 304 (CF-8) stainless steel | Powder coated cast iron | Cast Iron |

| Pump Shell | 304 heavy wall stainless steel | 304 heavy wall stainless steel | 304 heavy wall stainless steel |

| Staging* | Noryl® impellers and diffusers; type 304 stainless steel floating bearing inserts and acetal diffuser plates | Noryl® impellers and diffusers; type 304 stainless steel floating bearing inserts and acetal diffuser plates | Noryl® impellers and diffusers; type 304 stainless steel floating bearing inserts and acetal diffuser plates |

| Pump Shaft and Motor Coupling Assembly | 303 stainless steel hex shaft with 316 S.S. motor to shaft coupling | 416 stainless steel hex shaft with 316 S.S. motor to shaft coupling | 416 stainless steel hex shaft with 316 S.S. motor to shaft coupling |

| Shaft Seal | Carbon-silicon carbide, stainless steel spring, and Viton® | Carbon-silicon carbide, stainless steel spring, and Buna-N | Carbon-silicon carbide, stainless steel spring, and Buna-N |

| O-Rings | Viton® | Buna N | Buna-N |

| Motor US UL Std. No. 778 | Open drip proof (ODP) and Totally enclosed fan cooled (TEFC) motors available with single or three phase options. | ||

| *Replacement cartridge assembly available for all models. Includes all necessary parts to restore pumps to like-new performance. No special tools required. Noryl® is registered trademark of General Electric Vilton® is a registered trademark of Dupont | |||

| PRESSURE ADDED - PSI | 10 | 20 | 40 | 60 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 220 |

Max. Press. PSI | Suction Pipe Tap NPT | Disch. Pipe Tap NPT | |||||||||

| Stainless Steel Fitted | Powder- Coated Cast Iron Fitted |

Cast Iron Fitted |

HP |

Stage |

Output - Gallons per Minute

| |||||||||||||||||||

| 60Hz Models | ||||||||||||||||||||||||

| PB0508S031 | PB0508C031 | PB0508A031 | 1/3 | 8 | 10.2 | 9.6 | 8.3 | 6.5 | 4.3 |

|

|

|

|

|

|

| 96 |

3/4” |

3/4” | |||||

| PB0512S051 | PB0512C051 | PB0512A051 | 1/2 | 12 | 10.0 | 9.5 | 8.3 | 7.1 | 6.0 | 4.0 | 2.3 |

|

|

|

|

| 132 | |||||||

| PB0516S071 | PB0516C071 | PB0516A071 | 3/4 | 16 | 10.2 | 9.7 | 9.1 | 8.3 | 7.5 | 6.6 | 5.8 | 4.6 | 3.3 |

|

|

| 189 | |||||||

| PB0712S071 | PB0712C071 | PB0712A071 | 3/4 | 12 | 14.0 | 13.4 | 12.2 | 10.9 | 9.5 | 8.9 | 7.0 | 4.6 |

|

|

|

| 158 | |||||||

| PB1014S101 | PB1014C101 | PB1014A101 | 1 | 14 | * | * | 14.5 | 13.4 | 12.3 | 11.2 | 9.8 | 8.0 | 6.0 | 2.3 |

|

| 183 | |||||||

| PB1016S151 | PB1016C151 | PB1016A151 | 1-1/2 | 16 | * | * | 15.0 | 14.1 | 13.1 | 12.1 | 11.0 | 9.8 | 8.2 | 5.2 | 2.0 |

| 212 | |||||||

| PB1914S201 | PB1914C201 | PB1914A201 | 2 | 14 | 27.6 | 27.0 | 25.7 | 24.2 | 22.6 | 20.8 | 18.7 | 16.2 | 12.9 | 7.7 |

|

| 190 | |||||||

| PB3506S201 | PB3506C201 | PB3506A201 | 2 | 6 | 48.0 | 47.0 | 42.5 | 35.2 | 24.0 |

|

|

|

|

|

|

| 85 |

1” |

1” | |||||

| PB2711S201 | PB2711C201 | PB2711A201 | 2 | 11 | * | * | 31.5 | 29.5 | 27.1 | 24.2 | 20.3 | 13.0 |

|

|

|

| 147 | |||||||

| PB3508S301 | PB3508C301 | PB3508A301 | 3 | 8 | 48.0 | 47.5 | 44.0 | 40.0 | 35.2 | 27.5 |

|

|

|

|

|

| 118 | |||||||

| PB2714S301 | PB2714C301 | PB2714A301 | 3 | 14 | * | * | 33.0 | 31.5 | 29.8 | 27.9 | 25.6 | 22.8 | 18.9 | 11.1 |

|

| 187 | |||||||

| PB2717S303A** | - | - | 3 | 17 | * | * | * | 34.1 | 32.3 | 30.5 | 28.3 | 25.8 | 23.1 | 20.0 | 16.6 | 11.4 | 225 | |||||||

| - | - | PB5504A201 | 2 | 4 | 77.6 | 71.5 | 52.5 |

|

|

|

|

|

|

|

|

| 55 |

2” |

2” | |||||

| - | - | PB5506A301 | 3 | 6 | 77.8 | 74.4 | 65.0 | 51.1 | 31.9 |

|

|

|

|

|

|

| 83 | |||||||

| - | - | PB8504A201 | 2 | 4 | 105.8 | 90.0 | 47.0 |

|

|

|

|

|

|

|

|

| 49 | |||||||

| - | - | PB8505A301 | 3 | 5 | 108.8 | 98.8 | 60.0 | 25.0 |

|

|

|

|

|

|

|

| 60 | |||||||

| 50HZ Models | ||||||||||||||||||||||||

| PB0508Y031 | PB0508Z031 | PB0508X031 | 1/3 | 8 | 7.5 | 6.8 | 5.0 | 2.0 |

|

|

|

|

|

|

|

| 66 |

3/4" |

3/4" | |||||

| PB0514Y051 | PB0514Z051 | PB0514X051 | 1/2 | 14 | * | 7.3 | 6.4 | 5.3 | 4.0 | 2.1 |

|

|

|

|

|

| 113 | |||||||

| PB0714Y071 | PB0714Z071 | PB0714X071 | 3/4 | 14 | * | 10.9 | 9.7 | 8.5 | 7.0 | 5.2 | 2.8 |

|

|

|

|

| 132 | |||||||

| PB1020Y101 | PB1020Z101 | PB1020X101 | 1 | 20 | * | 13.0 | 12.2 | 11.4 | 10.5 | 9.5 | 8.2 | 6.8 | 5.0 | 2.0 |

|

| 183 | |||||||

| PB1022Y101 | PB1022Z101 | PB1022X101 | 1 | 22 | * | 12.0 | 12.2 | 11.4 | 10.5 | 9.5 | 8.4 | 7.4 | 6.0 | 4.3 | 2.0 |

| 203 | |||||||

| PB1023Y101 | PB1023Z101 | PB1023X101 | 1 | 23 | * | 12.0 | 12.2 | 11.4 | 10.5 | 9.6 | 8.6 | 7.6 | 6.5 | 5.1 | 3.3 |

| 213 | |||||||

| PB1920Y151 | PB1920Z151 | PB1920X151 | 1-1/2 | 20 | * | 22.1 | 21.0 | 19.5 | 18.0 | 16.1 | 14.1 | 11.6 | 8.3 | 2.0 |

|

| 182 | |||||||

| PB2717Y201 | PB2717Z201 | PB2717X201 | 2 | 17 | * | 30.8 | 28.9 | 26.7 | 24.1 | 21.2 | 18.0 | 13.5 |

|

|

|

| 160 |

1" |

1" | |||||

| PB3508Y151 | PB3508Z151 | PB3508X151 | 1-1/2 | 8 | * | 39.4 | 33.9 | 27.0 | 14.0 |

|

|

|

|

|

|

| 84 | |||||||

| PB3514Y301T | PB3514Z301T | PB3514X301T | 3 | 14 | * | * | 38.5 | 36.5 | 32.1 | 28.1 | 23.0 | 14.4 |

|

|

|

| 146 | |||||||

| Product Specifications | |

|---|---|

| MOTOR | 1/3-3 HP |

| HERTZ | 50/60 Hz |

| PHASE | Single or 3 Phase |

| RPM | 2950/3450 RPM |

| FLOW | 5, 7, 10, 19, 27, 35, 55 & 85 GPM |

| IMPELLER TYPE | Noryl® |

[/custom-specifications]

The Pressure Booster Pump is designed to increase water pressure from city mains or private water systems. Applications include pressure cleaning, spray or mist systems, jockey pumps, booster service, reverse osmosis, water circulation and general purpose pumping.

[/custom-usage]-

Very energy efficient pumps!

They were able to handle a big quantity for us more than once. Excellent

ENGLISH

ENGLISH

ESPAÑOL

ESPAÑOL العربية

العربية PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS