The Hydranautics® PRO-XP element series is a set of ultra high-pressure spiral wound membranes customized specifically for challenging industrial process applications such as brine dewatering. These membranes are based on existing Hydranautics high performance membrane products which have been specially designed to treat a variety of industrial feed streams including high fouling, high TDS, or chemically aggressive feeds.

[custom-specifications]

Specified Performance

- Permeate Flow (at initial test): 8,000 gpd (30.3 m3/d)

- Salt Rejection: 99.8% (99.7% minimum)

- Test Conditions: 32000 ppm NaCl solution

- 800 psig (5.5 MPa) Applied Pressure

- 77 °F (25 °C) Operating Temperature

- 10% Permeate Recovery

- 6.5 - 7.0 pH Range

*The Specified Performance is based on data taken after a minimum of 10 minutes of operation. Actual testing of elements may be done at conditions which vary from these exact values; in which case, the performance is normalized back to these standard conditions. Permeate flow for individual elements may vary ±15 percent from the value specified. Expect as much as 25% flux loss after operating near high pressure limits.

General Product Description

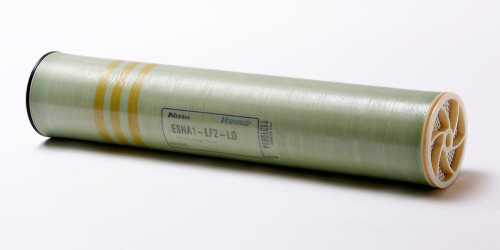

- Configuration: Spiral Wound

- Membrane Polymer: Composite Polyamide

- Membrane Active Area**: 330 ft2 (30.7 m2)

- Feed Spacer: 34 mil (0.86 mm)

Packaging: All membrane elements are supplied with a brine seal, interconnector, and O-rings. Elements are enclosed in a sealed polyethylene bag containing less than 1.0% sodium meta-bisulfite solution, and then packaged in a cardboard box

Element Details**

| A, Inches (mm) | B, Inches (mm) | C, Inches (mm) |

| 40.0 (1016) | 7.89 (200) | 1.125 (28.6) |

**Values listed are indicative, not specified. For more detailed specifications, see our Technical Service Bulletin documents or contact Hydranautics Technical Department.

Product Use and Restrictions

- Maximum Applied Pressure: 1800 psig (124 bar) up to 30°C (see Chart 1 for detail)

- Maximum Chlorine Concentration: < 0.1 ppm

- Maximum Operating Temperature: Pressure dependent (see Chart 1 for detail)

- pH Range, Continuous (Cleaning): 2-11 (1-13)

- Maximum Feedwater Turbidity: 1.0 NTU

- Maximum Feedwater SDI (15 mins): 5.0

- Maximum Feed Flow: 85 gpm (19.3 m3/h)

- Minimum Brine Flow: 12 gpm (2.7 m3/h)

- Maximum Pressure Drop for Each Element: 15 psi (0.10 MPa)

Note: The limitations shown here are for general use. For specified projects, operation at more conservative values may ensure the best performance and longest life of the membrane.

Table 1: Maximum pressure vs temperature

Max pressure Vs Temperature limits for

PRO-XP elements

| Max Pressure VS Temperature Limits for PRO-XP Elements | |||

| °F | °C | psi | bar |

| 33.8 | 1 | 1800 | 124.1 |

| 50 | 10 | 1800 | 124.1 |

| 68 | 20 | 1800 | 124.1 |

| 86 | 30 | 1800 | 124.1 |

| 95 | 35 | 1575 | 108.6 |

| 104 | 40 | 1325 | 91.4 |

| 113 | 45 | 1100 | 75.8 |

[/custom-specifications] [custom-features]

- Complements BWRO and SWRO by further increasing the solute concentration

- Reduces CAPEX and OPEX by downsizing the evaporator by reducing brine volume

- Increases the overall efficiency of ZLD / MLD systems

- Cost-effective, innovative, and sustainable

- Brine dewatering

- Municipal wastewater

- Landfill and leachates

- Pharmaceutical

- Mining water treatment

- Textile Industries

- Power & energy

[/custom-usage]

-

Fast!

I have been a faithful user of toray membranes for many years due to long-term consistency. Terrific products

ENGLISH

ENGLISH

ESPAÑOL

ESPAÑOL ???????

??????? PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS