Pure Aqua’s nanofiltration is a membrane filtration process used most often with low total dissolved solids water such as surface water and fresh groundwater, with the purpose of softening (polyvalent cation removal) and removal of disinfection by-product precursors such as natural organic matter and synthetic organic matter. Nanofiltration is also becoming more widely used in food processing applications such as dairy, for simultaneous concentration and partial (monovalent ion) demineralization.

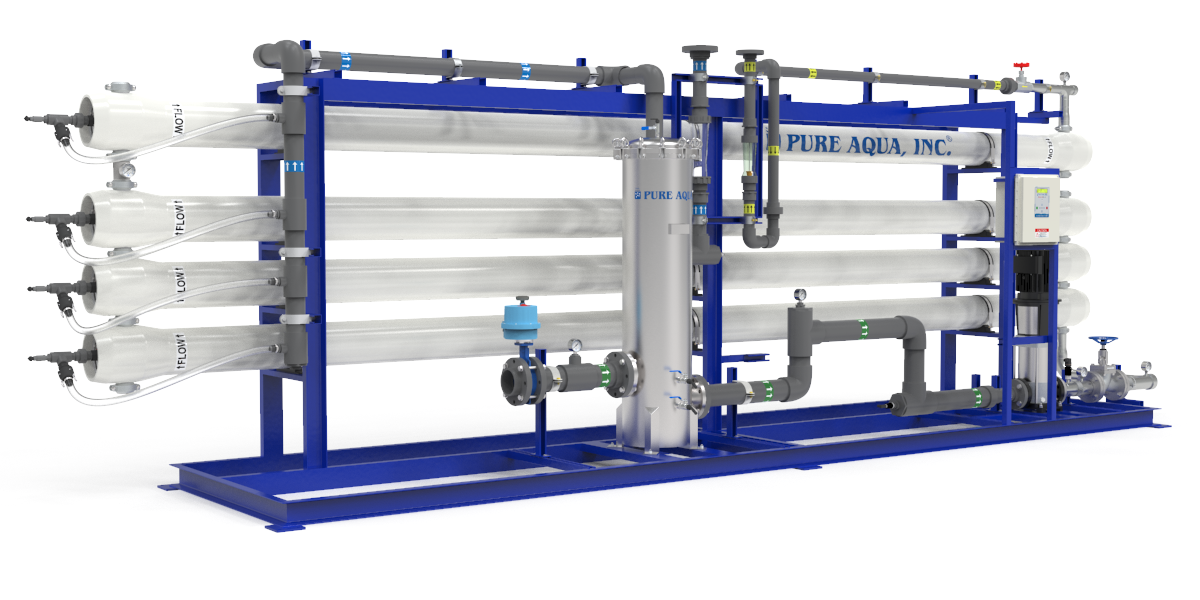

Pure Aqua supplies a full line of standard and fully customizable nanofiltration systems, all of which are engineered using advanced 3D computer modeling and process design software for accurate and customized solutions.

|

Operation Specifications: |

|

|---|---|

|

|

| Industrial Nanofiltration NFSystem NF-400 | ||||||

|---|---|---|---|---|---|---|

|

Model Number |

Permeate Flow Rate |

Quantity of 8" Membranes |

Motor Rating at 1,000 ppm 60Hz (hp) |

Approx. Weight (lbs) |

Dimensions L"xW"xH" |

|

|

GPD |

M3/D |

|||||

|

NF-25K-1480 |

25,200 |

95 |

4 |

5 |

2,300 |

190x43x61 |

|

NF-32K-1580 |

32,400 |

123 |

5 |

5 |

2,350 |

230x43x61 |

|

NF-38K-1680 |

38,700 |

146 |

6 |

5 |

2,400 |

270x43x61 |

|

NF-51K-2480 |

51,300 |

194 |

8 |

5 |

2,500 |

190x43x63 |

|

NF-64K-2580 |

64,800 |

245 |

10 |

10 |

2,600 |

230x43x65 |

|

NF-78K-3480 |

78,300 |

296 |

12 |

10 |

2,700 |

190x43x75 |

|

NF-97K-3580 |

97,200 |

368 |

15 |

10 |

3,200 |

230x43x75 |

|

NF-117K-3680 |

117,000 |

443 |

18 |

15 |

3,500 |

270x53x77 |

|

NF-129K-4580 |

129, 600 |

491 |

20 |

15 |

4,200 |

230x53x87 |

|

NF-155K-4680 |

155,700 |

589 |

24 |

15 |

4,550 |

270x53x88 |

Note: The above information is to be confirmed after providing detailed water analysis. Nanofiltration systems are the same as RO systems, and must have good pretreatment and antiscalant dosing systems.

[/custom-specifications]

|

Standard Features: |

Available Options: |

|---|---|

|

|

Nanofiltration is also becoming more widely used in food processing applications such as textile industry wastewater treatment, dairy, for simultaneous concentration and partial (monovalent ion) demineralization.

Here at Pure Aqua, Inc., we engineer and build all of our water treatment systems in-house.

Our turn-key water treatment systems are all pre-engineered using the latest CAD technology available.

This enables our teams to build and deliver treatment systems to our customers with quick turnaround times.

Many of our customers require custom engineered systems. These are typically built around similar core systems and thus allowing for improved turnaround times, even for one-off designs.

-

great softening membrane system

We bought a nanofiltration system to replace our conventional water softener, it was the best thing we did, we saved money on salt and operation. Water quality is superior, great product.

- 360view:

- https://cdn11.bigcommerce.com/s-1x0ys7yqwf/content/360Views/RO-400_173k.2.html

- 360image:

- https://cdn11.bigcommerce.com/s-1x0ys7yqwf/product_images/uploaded_images/360view-wireframe-small.jpg

ENGLISH

ENGLISH

ESPAÑOL

ESPAÑOL العربية

العربية PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS