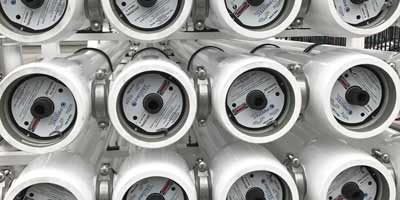

We understand that these products are expected to last the entire life of the RO system. In order to help ensure the life of the pressure vessel, we have selected the best materials and use the best fabrication methods available in the manufacturing of our products. When you select PROTEC™ products, here are some of the benefits you receive:

- Leak Free Reliability

- First Time Quality

- Metal & Plastic Components

- Operational Ease

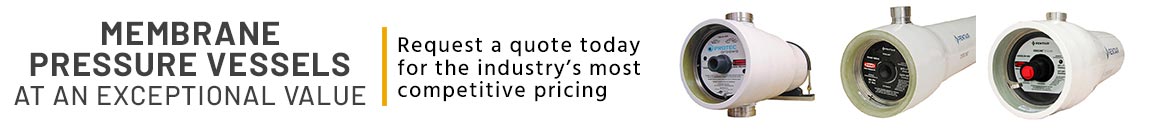

PROTEC 4" END PORTED

- Standard 4"x 40" Elements

- 300 - 1,000 PSI

- End Port Flow

- 1-6 Element Lengths

PROTEC 4" SIDE PORTED

- Standard 4"x 40" Elements

- 300 & 450 PSI

- Side Port Flow

- 1-6 Element Lengths

PROTEC 8" END PORTED

- Standard 8"x 40" Elements

- 150 - 1,200 PSI

- End Port Flow

- 1-8 Element Lengths

PROTEC 8" SIDE PORTED

- Standard 8" x 40" Elements

- 150 - 1,200 PSI

- Side Port Flow

- Available ASME Stamp

PROTEC 8" MEGA SIDE PORT MSP

- Standard 8" x 40" Elements

- 150 - 1,200 PSI

- Side Port Flow

- Available ASME Stamp

PROTEC 2.5" End PORTED

- Standard 2.5" x 40" Elements

- 14" & 21" Lengths Available

- End Port Flow

- 1-2 Element Lengths

- 1,200 PSI

Pure Aqua has over 20 years of experience as a global provider of Protec Pressure Vessels designed for sustained use as a housing for membrane - based components to treat typical bodies of water with up to 1000 PSI at higher pressures. The structure will satisfy any four-inch nominal diameter spiral-wound element and the many other elements of hollow fibre.

Operational Excellence and First Time Quality

Allowing Protec Arisawa to meet the highest level of quality, scheduled shipments and other customer expectations.

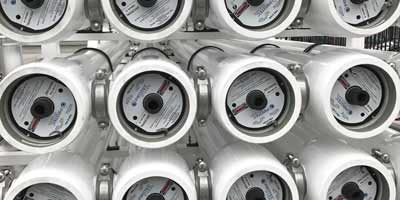

Leak Free Reliability

PROTEC™ pressure vessels are tested as an assembly including the specific heads that will be shipped with each vessel. This attention to detail allows us to claim the best leak-free reliability record in the industry. We understand that no one likes to deal with leaks caused by poor workmanship, low quality materials and insufficient in-house testing. With Protec Arisawa, you receive high quality leak-free vessels, first time every time.

Pressure Vessels Available with an ASME Code Stamp Upon request. The ASME Code is an internationally recognized safety standard written specifically for fiber reinforced plastic pressure vessels.

-

Systems

-

Parts

-

Expertise

- All Expertise

- Engineered Solutions

-

Water Treatment Applications

- Hydrogen Production

- Poultry

- Solar Panels

- Agriculture

- Desalination

- Golf Courses

- Lithium Mining

- Water Stores

- Window Washing

- Aerospace

- Boiler Feed

- Dairy

- Disaster Relief

- Drinking Water

- Environmental

- Fish Hatcheries

- Food & Beverage

- Hospital

- Hotel

- Ice Making

- Laundry

- Marine

- Military

- Mining

- Municipal

- Offshore

- Pharmaceutical

- Power & Energy

- Refinery

- Restaurants

- Semiconductor

- Spot Free

- Wastewater

- Water Treatment Projects

- Regional Expertise

-

Resources

-

About Us

ENGLISH

ENGLISH

ESPAÑOL

ESPAÑOL العربية

العربية PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS