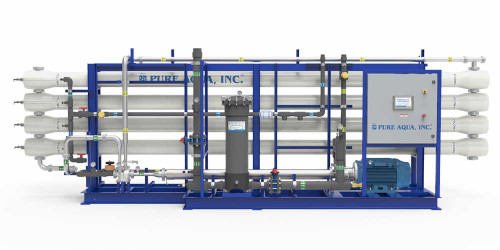

Pure Aqua, Inc. manufactures a full line of cruise ro watermakers designed for heavy-duty or continuous service within on and offshore applications requiring marine desalination systems.

Compact & Durable

Pure Aqua Seawater Reverse Osmosis Systems feature a unique and innovative compact design that allows for easy installation in any size area. The high grade corrosion resistant powder coated frame features a modular design that allows for the system to be divided into multiple assemblies for easier mounting. The SWC-Series is also equipped with premium components which include duplex SS centrifugal-type high pressure pump for high performance and corrosion resistance, a programmable computer controller with many built-in features, 1000 psi fiberglass membrane housings for durability and US made seawater membranes for high quality product water.

SWC Series Capacity

Our SWC Series is available with capacities ranging from 380 GPD to 10,000 GPD and a maximum feed water TDS of 42,000 ppm. We offer standard SWC Series units as well as customizable to fit you water application needs. Whether it's for your luxury yacht, cruise line, or for a five star resort on the beach, Pure Aqua has the right desalination system for you project.

Customizable For Your Needs

When your needs demand continuous-duty, commercial-grade watermaking, the solution is very clear. The Pure Aqua reverse osmosis water maker is efficient and extremely reliable. These marine desalination systems deliver great volumes of potable fresh water with capacities ranging between 380 to 10,000 GPD. Ideal for commercial vessels, island homes, oil platforms, hotels, or large yachts. These water makers convert salt water to fresh water and provide service wherever clean, pure, fresh water is needed. Employing our advanced microprocessor control panel, our saltwater to freshwater converter enables state-of-the-art, total control and user-friendly system customization.

Choosing the right watermaker for boats

Before advancements in desalination technology, having a water maker aboard a cruising boat was considered as a desirable luxury item. Today, most sailboats carry a reverse osmosis system, which improves the overall experience of setting sail, specifically in areas where freshwater is unavailable. While water makers might not be required for boats near dockside, boaters cruising throughout offshore locations depend on the sailboat water maker for daily hydration. Long-term voyages on sea is made much more convenient with a quality watermaker onboard and possible for boaters who dream about living living off the grid. Other basic necessities such as showering and cooking are made possible by sailing with a cruise ro watermaker.

How does a marine water maker work?

Obtaining fresh water is taken for granted in many geographical locations such as in urban areas within developed countries. However, such locations do not afford people with the ease of attaining freshwater supplies in sufficient quantities to drink and use in other applications. For instance, hot/arid areas and remote islands throughout the world provide very few water sources to the people who inhabit these specific regions. One application which depends solely on the usage of a marine water maker for the production of freshwater is offshore installations. As ships cruise further offshore and away from any means of freshwater production from natural sources such as rivers, lakes, springs, and wells, the only real chance of acquiring clean water is from the ocean itself.

While the ocean provides an abundant amount of water to marine water boats, it contains extremely high concentrations of salt, which makes it unusable in virtually any application, including consumption. To remedy this issue, boat owners that look to spend a great deal of time off-shore, make sure to carry a marine water maker on board in order to convert seawater into purified, freshwater. The water produced from marine water makers are of the highest quality and can be used for drinking, washing, showering, etc.

A boat water maker works by utilizing the process of reverse osmosis which specifically targets impurities in water such as salt and minerals and excluding them from the finished product water. This is done through the employment of pressure pumps, which pushes the untreated water through semi-permeable membrane elements that use small pores to filter out these unwanted contaminants from passing along with the water. The contaminants are subsequently flushed away, and the newly purified water is kept and ready to be used. High-pressure pumps are required to use for treatment operations regarding seawater since it possesses greater degrees of salt and other pollutants. A quality sailboat water maker is proven to eliminate up to 99 percent of dissolved salt and minerals from seawater.

Maintenance for watermaker

Watermakers have developed a reputation for becoming hard to sustain over a period of time, but over the years the machinery has changed and, generally, daily maintenance has been made much simpler. However, keeping your water maker polished for quality performance is critical. A boat water maker that is operated in polluted harbors will inevitably lead to clogged parts and require frequent adjustments to the filter media. Boaters can scrape through by having more filters on board but it is ill-advised. The climate is much safer inside the open sea and isolated anchorages. Remember as well the shallowness of the water where you are anchored, since the possibility of tidal movements will often occur and stir up small particles and sediments. This may also lead to additional adjustments in the filter and may even affect other parts. An automatic freshwater flush is a good choice that will clean the membrane portion of the marine water maker after use. It means keeping the housing of the membrane vessel safe from any organic matter which might foul the membrane and lower the capacity to generate fresh water.

For more information regarding our watermakers, visit the benefits of desalination blog post.

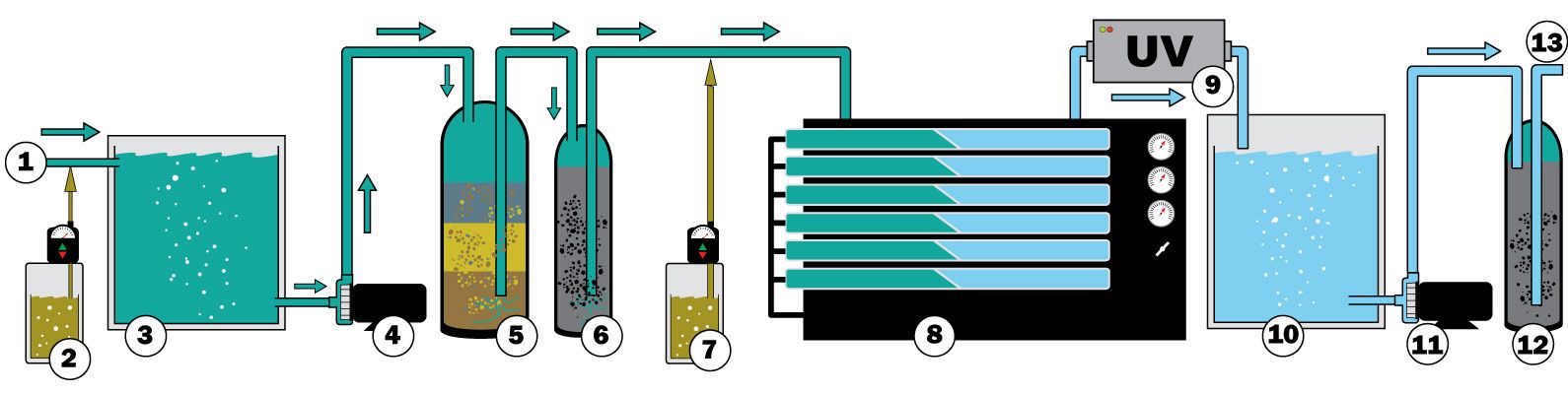

Commercial Seawater Watermaker System Process Schematic Diagram

|

1 |

Feed raw water |

|

2 |

Pre-chlorination dosing system |

|

3 |

Raw water storage tank |

|

4 |

Feed and backwash pump |

|

5 |

Multi media filter for turbidity and suspended solids reduction |

|

6 |

Activated carbon filter for chlorine, odor, taste, organic removal |

|

7 |

Antiscalant dosing system |

|

8 |

Commercial seawater reverse osmosis system |

|

9 |

|

|

10 |

Product water tank |

|

11 |

Repressurization pump |

|

12 |

Calcite filter for post pH neutralization |

|

13 |

Treated water to use |

In choosing the correct water maker model, the following information must be provided:

- Flow rate (GPD, m3/day, etc.)

- Feed water TDS or sea source (ex: Pacific, Mediterranean, etc.)

- Seawater Source (open intake or beach well)

- Iron, manganese, and hydrogen sulfide must be removed before the water enters the reverse osmosis unit

- TSS must be removed before commercial SWC system

- Turbidity should be removed

- SDI must be less than 3

- Water should be free from oil and grease

- Chlorine must be removed

- Available voltage, phase, and frequency

- Dimensions of proposed area where commercial SWC System will be installed

Reverse osmosis system for boats cost depends on the pre and post-treatment equipment selected, such as:

- Prechlorination dosing

- Media filter

- Carbon filter

- Antiscalant dosing

- NSF components

- Advanced controller

- Advanced instruments

- Iron removal filter

- High TDS application, up to 50,000 ppm

- Skid mounted system

- Calcite filter

- Three phase system power

- Variable frequency drive VFD

- Fresh water flush

- Membrane cleaning skid

|

Operation Specifications |

||

|

|

|

|

Model No. |

Permeate |

Membranes |

Motor HP |

Approx. |

Dimensions |

|||||

|---|---|---|---|---|---|---|---|---|---|---|

|

GPD |

M3/Day |

Size |

Qty |

60 HZ |

50 HZ |

LBS. |

L"xW"xH" |

|||

|

SW-0.38K-125 |

380 |

1.4 |

2.5" x 40" |

1 |

2 |

2 |

220 |

51X21X30 |

||

|

SW-0.75K-225 |

750 |

2.8 |

2.5" x 40" |

2 |

2 |

2 |

230 |

51X21X30 |

||

|

SW-1.1K-325 |

1,100 |

4.2 |

2.5" x 40" |

3 |

2 |

2 |

250 |

51X21X30 |

||

|

SW-1.5K-425 |

1,500 |

5.7 |

2.5" x 40" |

4 |

3 |

3 |

290 |

51X21X30 |

||

|

SW-1.0K-104 |

1,000 |

3.8 |

4" x 40" |

1 |

3 |

5 |

395 |

61X34X42 |

||

|

SW-2.0K-204 |

2,000 |

7.8 |

4" x 40" |

2 |

5 |

5 |

500 |

61X34X42 |

||

|

SW-3.0K-304 |

3,000 |

11.3 |

4" x 40" |

3 |

5 |

5 |

360 |

61X34X42 |

||

|

SW-4.0K-404 |

4,000 |

15.1 |

4" x 40" |

4 |

7.5 |

7.5 |

500 |

61X34X42 |

||

|

SW-5.0K-504 |

5,000 |

18.9 |

4" x 40" |

5 |

7.5 |

7.5 |

750 |

61X34X42 |

||

|

SW-6.0K-604 |

6,000 |

22.7 |

4" x 40" |

6 |

7.5 |

7.5 |

850 |

61X34X56 |

||

|

SW-7.0K-704 |

7,000 |

26.5 |

4" x 40" |

7 |

10 |

10 |

970 |

61X34X56 |

||

|

SW-8.0K-804 |

8,000 |

30.3 |

4" x 40" |

8 |

10 |

10 |

1,050 |

61X34X61 |

||

|

SW-10K-1004 |

10,000 |

37.9 |

4" x 40" |

10 |

15 |

15 |

1,150 |

61X34X61 |

||

|

For more information, please view/download our "Data Sheet" |

||||||||||

[/custom-specifications]

|

Standard Features: |

Available Options: |

|

|

[/custom-features]

|

Ideal applications for a Reverse Osmosis Water Maker include: |

||

|

|

|

Here at Pure Aqua, Inc., we engineer and build all of our water treatment systems in-house.

Our turn-key water treatment systems are all pre-engineered using the latest CAD technology available.

This enables our teams to build and deliver treatment systems to our customers with quick turnaround times.

Many of our customers require custom engineered systems. These are typically built around similar core systems and thus allowing for improved turnaround times, even for one-off designs.

-

We are very satisfied with our investment.

You get what you pay for is what I can say with this compact SWRO system. There are lots of cheap SWRO here in Asia but the overall quality is cheap and un-reliable as well. We have ordered this SWRO from Pure Aqua (SW-6.0K) and shipped to the Philippines and now being used in a small coastal town for commercial water filling station. The quality of the filtered water is great and we already have recovered our investment while the system is still running consistently producing same quality of good tasting water for the buying customers. We are very satisfied with our investment.

-

Very reliable system.

Our company needs a skidded SWRO where we can mount the system on any pick-up truck and provide needed water in any parts where drinking water is needed. We can easily access any beach well and produce drinking water to any village who needs them. We chose this SW-5.6K-604 with included pre-treatment in the skid. We have them ship the system here in Kenya and it has been working well for almost a year now with no issues. Very reliable system.

-

We didn't regret choosing this over other similar systems

We are in an island in Canada and need a back-up supply of fresh water during spring when our source gets dirty during melting of snow. We have this unit from Pure Aqua which produces around 1,800 Gallons per day of fresh water from a beach well. The equipment is sturdy and very easy to operate. We can find another similar equipment in the market but we felt this is the best compact designed system that we can buy and we didn't regret choosing this over other similar systems.

-

Availability image of Imports

good product

-

filters particulate is excellent

I have tried many suppliers before, this is a great source for string wound PP sediment cartridges, it is multi depth, it makes the element to live more with excellent filtration. I highly recommend this product.

- 360view:

- https://cdn11.bigcommerce.com/s-1x0ys7yqwf/content/360Views/SW-10K-1004.1.html

- 360image:

- https://cdn11.bigcommerce.com/s-1x0ys7yqwf/product_images/uploaded_images/360view-wireframe-small.jpg

ENGLISH

ENGLISH

ESPAÑOL

ESPAÑOL العربية

العربية PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS