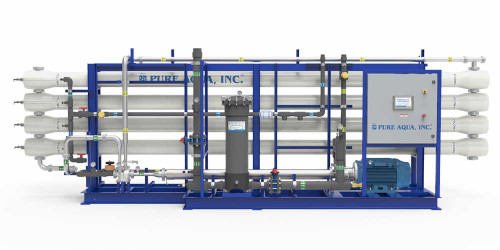

For continuous or heavy-duty service in marine applications on and off shore, Pure Aqua manufactures a full line of designed seawater desalination systems.

Desalination System For Potable Water Applications

Seawater Reverse Osmosis (SWRO) is a reverse osmosis desalination membrane process that has been commercially used since the early 1970s. These systems can vary from large desalination plants to a smaller sized seawater to drinking water machine. The typical single pass seawater treatment system consists of the following components:

- Intake: beach well water

- Pre-treatment: Filtration and chemical dosing

- High-pressure pump: to achieve the needed pressure

- Membrane assembly: to perform the desalination process

- pH adjustment: to adjust the alkalinity or acid level

- Disinfection: to prevent any bacterial or organic growth

Pure Aqua, Inc. has manufactured and supplied hundreds of commercial and industrial seawater reverse osmosis desalination systems with feed water TDS up to 45,000 ppm.

Customizable Desalination Machine Capacity

Our SWI Series is available with capacities ranging from 8,000 GPD to 660,000 GPD and a maximum feed water TDS of 42,000 ppm. We offer standard SWI Series units as well as customizable to fit you water application needs. From your five star resort to the world's largest desalination plant in the United Arab Emirates, Pure Aqua is ready and able to provide only the best in industrial desalination systems.

Pure Aqua’s desalination machines are capable of removing salts as well as other impurities such as bacteria, sugars, proteins, dyes and constituents that have a molecular weight greater than 150-250 Dalton. Pure Aqua supplies a full line of standard and customizable seawater reverse osmosis desalination systems, all of which are engineered using advanced 3D computer modeling and process design software for accurate and customized solutions.

Questions & Answers

What is a desalination system?

Desalination systems have become an important pillar of the world’s freshwater supplies. Desalination provides an alternative to insufficient clean water production and natural causes which exacerbates this issue such as droughts. Independent of weather patterns, desalination systems are efficient in helping countries or companies in reaching their water demands.

Desalination systems utilize reverse osmosis to purify unwanted contaminants such as salt and minerals from untreated water. This process works through applying high-pressure pumps that force the concentrated water through semi-permeable membranes which consist of small pores that prevent the impurities from passing through. What results from the reverse osmosis system is fresh, clean water that is free of its pollutants which are simultaneously discharged.

Desalination systems are generally used in large-scale plants that must deal with regulatory, budgetary, and practical issues to produce economical and eco-friendly water distribution. There are hundreds of desalination plants throughout the world that are depended upon by regions for economic activity and clean water supplies. Desalination continues to provide solutions that prove its worth by meeting challenging criteria with stellar answers and productivity.

Vist our page - benefits of desalination for more information.

Where are desalination systems becoming increasingly popular?

While desalination systems are becoming a common application throughout the world, certain regions have higher concentrations due to greater water demands. There are estimates of up to 18,000 existing desalination plants that utilize these systems globally, generating more than 25,000 GPD. Almost half of these desalination machines exist and operate in the Middle East and North Africa. This occurrence is unsurprising due to the hot and arid climate of these particular regions.

Although desalination systems continue to grow in usage in those regions, it is expected to intensify in development over the next few decades throughout the United States, Asia, and Latin America. Technology advances in these areas will eventually drive down the percentage of energy needed for water production, which ultimately results in more active desalination systems.

Is a desalination machine cost-effective?

Desalination machines have been known to be very expensive to build and maintain over a long period of time. However, recent enhancements in water treatment components which includes reverse osmosis membrane advancements (high rejection, low energy costs) and energy recovery devices, have made the associated costs of desalination plants much lower. To such an extent that desalination machines have now become a cost-effective alternative source of water distribution. For this reason, most regional and state governments have incorporated them into their water plans as tools to help meet the present and future water goals.

|

Operation Specifications |

||

|

|

|

|

Model # |

Permeate Flow Rate |

Quantity of 8” Membranes (Single Stage) |

Motor Rating HP at 42,000 ppm |

Approx. Weight (lbs) |

Dimensions L”xW”xH” |

||

|

gpd |

m3/d |

60Hz |

50Hz |

||||

|

SW-8K-1280 |

8,000 |

30 |

2 |

15 |

15 |

2,600 |

110x40x60 |

|

SW-12K-1380 |

12,000 |

45 |

3 |

15 |

20 |

2,650 |

150x40x60 |

|

SW-16K-1480 |

16,000 |

61 |

4 |

25 |

25 |

2,700 |

195x50x70 |

|

SW-20K-1580 |

20,000 |

76 |

5 |

25 |

25 |

3,000 |

225x50x75 |

|

SW-24K-2380 |

24,000 |

91 |

6 |

30 |

30 |

3,200 |

150x40x60 |

|

SW-32K-2480 |

32,000 |

121 |

8 |

40 |

40 |

4,200 |

195x50x70 |

|

SW-48K-2680 |

48,000 |

182 |

12 |

40 |

50 |

5,600 |

280x60x75 |

|

SW-64K-4480 |

64,000 |

242 |

16 |

60 |

60 |

6,500 |

195x60x75 |

|

SW-72K-3680 |

72,000 |

273 |

18 |

75 |

75 |

12,000 |

280x60x75 |

|

SW-96K-4680 |

96,000 |

363 |

24 |

75 |

75 |

13,000 |

280x65x75 |

|

SW-120K-5680 |

120,000 |

454 |

30 |

100 |

100 |

14,000 |

280x70x90 |

|

SW-144K-6680 |

144,000 |

545 |

36 |

125 |

125 |

15,000 |

280x80x75 |

|

SW-168K-6780 |

168,000 |

636 |

42 |

125 |

125 |

16,000 |

325x80x85 |

|

SW-196K-7780 |

196,000 |

742 |

49 |

150 |

150 |

16,500 |

325x80x85 |

|

SW-224K-8780 |

224,000 |

848 |

56 |

200 |

200 |

17,000 |

325x80x85 |

|

SW-252K-9780 |

252,000 |

954 |

63 |

200 |

200 |

18,000 |

325x80x90 |

|

SW-280K-10780 |

280,000 |

1,060 |

70 |

200 |

200 |

19,000 |

325x80x95 |

|

SW-336K-12780 |

336,000 |

1,272 |

84 |

250 |

250 |

20,000 |

325x80x100 |

|

SW-420K-15780 |

420,000 |

1,590 |

105 |

300 |

300 |

21,200 |

325x80x100 |

|

SW-504K-18780 |

504,000 |

1,908 |

126 |

350 |

350 |

22,000 |

425x188x110 |

|

SW-560K-20780 |

560,000 |

2,120 |

140 |

400 |

400 |

27,000 |

425x190x110 |

|

SW-672K-24780 |

672,000 |

2,544 |

168 |

500 |

500 |

30,000 |

425x200x110 |

|

SW-840K-30780 |

840,000 |

3,179 |

210 |

600 |

600 |

35,000 |

425x250x110 |

|

For more information, please view/download our "Data Sheet" |

|||||||

[/custom-specifications]

|

Standard Features |

Available Options |

|

|

[/custom-features]

|

The ideal applications for an Industrial Seawater RO system include: |

||

|

|

|

Here at Pure Aqua, Inc., we engineer and build all of our water treatment systems in-house.

Our turn-key water treatment systems are all pre-engineered using the latest CAD technology available.

This enables our teams to build and deliver treatment systems to our customers with quick turnaround times.

Many of our customers require custom engineered systems. These are typically built around similar core systems and thus allowing for improved turnaround times, even for one-off designs.

-

Excellent designed SWRO.

Excellent designed SWRO. They used Dow sea water RO membrane in our system (SW-96K) and other components are excellent industrial brands too

-

Best price!!

We went with price and recovery rate design when we chose to purchase this Pure Aqua SWRO. We have the SW-136K-6680. Great system.

-

Pricing is very competitive

Pricing is very competitive compared to huge name companies that's why we decided to go with their SW-96K-4680. We are glad we went with Pure Aqua.

-

Everything is exceptional.

I will recommend this company for anybody who is looking for RO systems. We bought their SW-16K-1480 and everything is exceptional.

-

Engineers at Pure Aqua are knowledgeable

Engineers at Pure Aqua are knowledgeable and their SWRO quality is unbeatable. We have the SW-112K-4780 in our plant.

-

Great SWRO system

Great SWRO system and great after sales support. Our SW-168K-6780 produces 110 GPM of fresh water consistently day-after-day.

-

Great buy.

Works well and our team maintains the SWRO very well too. System came with very detailed manuals that are easy to follow. Great buy.

-

Nice clean design

Nice clean design and I like how they arranged the racks of vessels and piping. The actual SWRO is even better than the 3D drawing that we saw.

-

The system is designed very well.

The system is designed very well. Pre-Treatment provided covers everything that are needed to protect the membranes. Our SWRO produces 35 GPM of permeate with around 200 ppm of salinity level. Great quality.

- 360view:

- https://cdn11.bigcommerce.com/s-1x0ys7yqwf/content/360Views/SWI-96K.html

- 360image:

- https://cdn11.bigcommerce.com/s-1x0ys7yqwf/product_images/uploaded_images/360view-wireframe-small.jpg

ENGLISH

ENGLISH

ESPAÑOL

ESPAÑOL العربية

العربية PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS