Hydranautics is a world-wide supplier of separation membrane technology with a comprehensive list of top-performing filtration products for various industries. Applications which include boiler feedwater treatment, wastewater treatment, seawater desalination, surface water treatment, drinking water purification, agricultural water treatment, and pharmaceutical water purification.

Hydranautic membrane products are designed with the goal of delivering unmatched quality in terms of product and technical mastery. They are depended upon by several large manufacturing sites throughout the world in countries such as USA, China, Canada, Japan, Mexico, etc.

- 2.5", 4", & 8" Sizes

- High Rejection

- High Recovery

- Reduced Fouling Potential

- Enhanced Durability

- Sanitary & Full Fit

- 2.5'', 4" & 8" Sizes

- High Rejection

- High Recovery

- Reduced Fouling Potential

- Enhanced Durability

- Low Temp. Models

- 4" & 8" Sizes Available

- 50%-90% Salt Rejection

- High Hardness Rejection

- Reduced Colloidal Fouling

- Enhanced Durability

- Low Operating Pressure

- NSF61 Certification

- High quality Potable Water

- Superior Pre Treatment

- Low Fouling Hydrophilic

- Enhanced Durability

- Modular Elements

- 4", & 8" Sizes Available

- Specialty Applications

- Enhanced Recovery

- Reduced Fouling Potential

- Enhanced Durability

- Sanitary & Full Fit

Pure Aqua has over 20 years of experience as a global provider of brackish, seawater, nanofiltration, and ultrafiltration membranes from one of the leading membrane manufacturers in the world, Hydranautics. These membranes work in providing users with high flow rate, low energy and fouling.

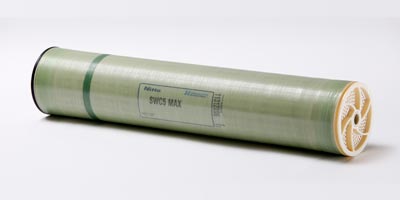

Hydranautics membranes continuously meet and satisfy the increasing demands of the water treatment industry through their high productivity, outstanding performance, salt rejection, productivity, and savings. These membranes set high performance standards for the reverse osmosis membrane elements which deliver the highest salt rejection rates available. They can range in size from 4” to 8” elements, delivering the highest levels of salt rejection and an always pure end product. They are designed to accommodate varying levels of seawater salinities worldwide with dependable field-proven performance.

Hydranautics membranes lower fouling in waste and surface water while having a high fouling potential for reuse and reclaimed applications. These membranes offer superior membrane technology to lower membrane fouling and treatments to treat difficult feed and municipal wastewater. To this point, these applications have significantly required a pretreatment before exposing them to a composite polyamide membrane. These membranes are manufactured with a thicker brine spacer which reduces the Delta P, meeting the increased demand for reduced fouling membranes. This permits a lesser need for frequent cleanings while maintaining a high permeate flow.

Hydranautics membranes are designed for water treatment systems and comprise of a thin film of polymer materials casted onto a cloth frame many times Angstroms thick. These commercially available membranes should have high water permeability and a greater standard of semipermeability; that is, the water delivery rate would have to be much larger than that of the dissolved ion transfer rate. The membrane should be flexible and have superior mechanical reliability over a large broad ph range and temperatures. The consistency at ground conditions of these substances over a number of years determines the economically valuable membrane life, which is within a span of 3 to 5 years. There are two main groups of polymer composites that could be used to create acceptable frameworks of the reverse osmosis: cellulose acetate (CAB) and composite polyamide (CPA). For each category of polymeric material, the development, operational requirements, and efficiency of the membranes differ considerably.

Membranes manufactured from Hydranautics are considered as the customary RO membrane elements in the industry. These components provide more than half a billion gallons of freshwater per day for the world's factories and drinking supplies. The semiconductor industry depend on Hydranautics membranes to deliver ultrapure water necessary to produce sensitive semiconductor chips. CPA membranes are specifically suitable for turning out make-up water that has low-scaling for power generation utilizations due to elevated TOC, silica and hardness reduction. These membranes require less maintenance and more productivity throughout power plants, thus greatly lowering downstream refining ion exchange costs. CPA membranes have the maximum possible rate of salt-rejection.

ESPA are designed with energy saving poly amide which contains membrane elements of Hydranautics for reduced feed pressure. The ESPA series of components are suitable for industrial & drinking water supplies where the main driving force for membrane choice is the power consumption. The ESPA2-LD membrane throughout the ESPA series consists of the maximum rejecting capability with a 99.5 percent rejection of salts (at normal testing conditions). The ESPA2-LD is a fine balance for saving energy among high rejection and reduced pressure. The ESPA4-LD offers the most minimal operating pressure requirement of every other 100psi Hydranautics product as well as being a great alternative for drinking water systems where a certain salt passage is needed or for implementations where the preferred pollutant removal organisms including nitrates or sulfates are simpler to remove.

Hydranautics Standard Features

- High Rejection

- Sea Water Membranes

- LFC Membranes for Low Fouling

- SanRO Membranes for Sanitary or Full Fit

Hydranautics Membranes

- ESPA: Low Energy/High Flow Tap & Brackish Water Thin Film Membranes

- CPA: High Rejection Tap & Brackish Water Thin Film Membranes

- SWC: Seawater Membranes

- LFC: Low Fouling Membranes

ENGLISH

ENGLISH ESPAÑOL

ESPAÑOL العربية

العربية PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS